INDUSTRIES SERVED

Pharmaceutical

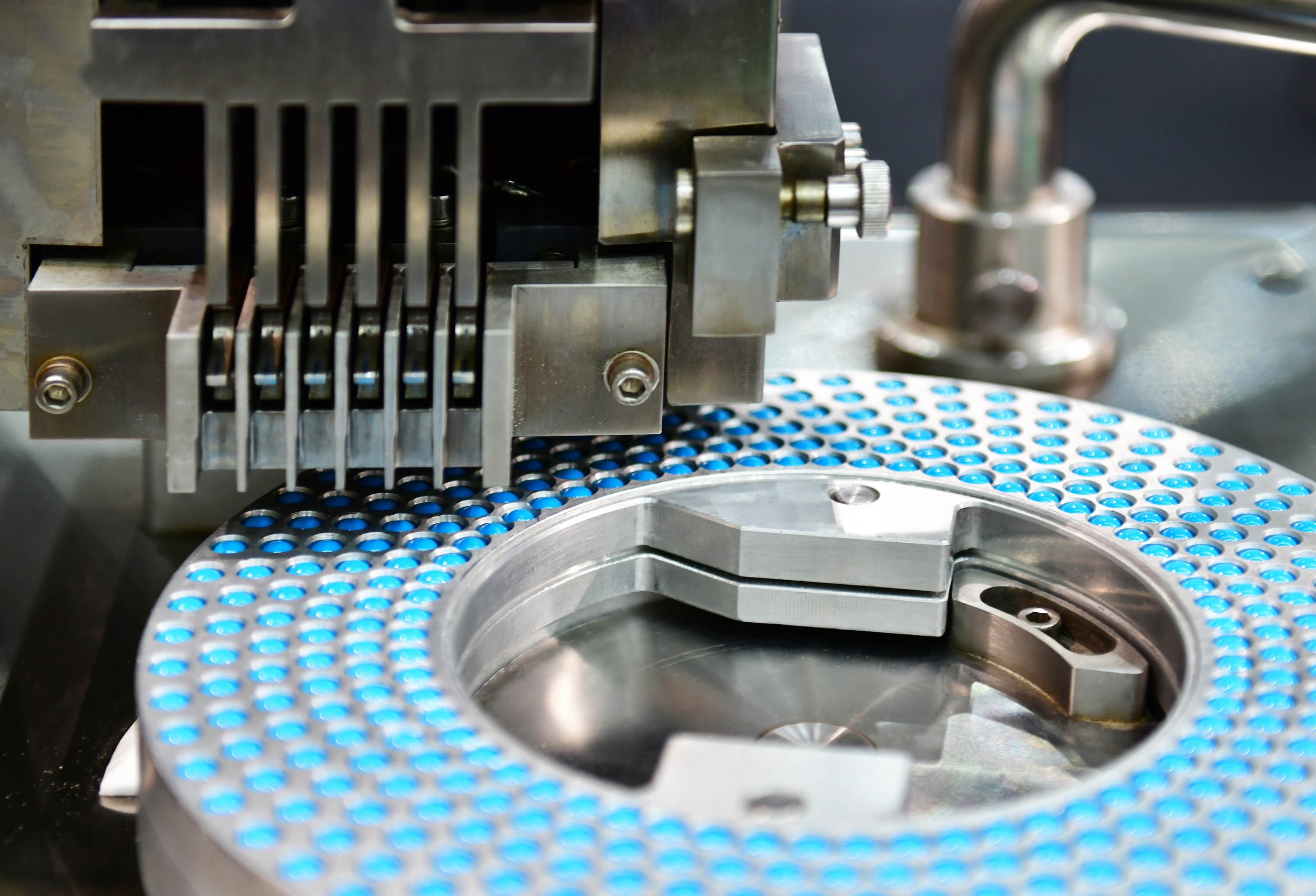

The pharmaceutical manufacturing industry stands at the cusp of a transformative era with the advent of Industry 4.0 technologies. This fourth industrial revolution integrates advanced automation, data analytics, artificial intelligence, and the Internet of Things (IoT) to create smart manufacturing environments. The adoption of these technologies promises to enhance efficiency, improve product quality, and facilitate compliance with regulatory standards, thereby revolutionizing traditional pharmaceutical practices.

Quality assurance is a critical area where I4.0 technology can make a significant impact. The integration of advanced automation and Detect-It's visual AI in manufacturing processes reduces the likelihood of human error, which is paramount in an industry where product safety and efficacy are crucial. Automated systems can perform repetitive tasks with precision, ensuring consistent product quality. Furthermore, digital technologies facilitate more rigorous tracking and documentation, making it easier to comply with stringent regulatory requirements.

Moreover, the use of Detect-It Net Evidence enables pharmaceutical companies to gain deeper insights into their manufacturing processes. By analyzing vast amounts of data generated during production, companies can identify trends, detect anomalies, and predict potential failures. This proactive approach to maintenance and quality control enhances decision-making processes, leading to more informed strategic planning and risk management.

Detect-It AI can help Pharmaceutical manufacturers in many ways:

Quality Control: Detect-It can be used to inspect products on production lines, identifying defects or inconsistencies in packaging, labeling, or the product itself. This reduces human error and ensures higher quality standards.

Process Monitoring: By analyzing visual and sound data from cameras and sensors installed in manufacturing facilities, Detect-It AI can monitor equipment performance, detect anomalies, and predict maintenance needs, thereby reducing downtime and improving efficiency.

Compliance and Regulation: Detect-It AI can help ensure that manufacturing processes adhere to regulatory standards by automatically checking for compliance with established protocols in real-time.

Supply Chain Management: Detect-It AI can optimize inventory management by visually tracking materials and products throughout the supply chain, identifying shortages or delays early on.

Data Visualization: Detect-It Net Evidence can process and visualize large datasets from manufacturing processes, helping decision-makers identify trends and make informed choices based on real-time data.

Remote Monitoring: Detect-It AI can enable remote inspection and monitoring of manufacturing processes, allowing experts to assess situations without being physically present, which is especially useful during crises or in hard-to-reach locations.

The implementation of Industry 4.0 technologies in pharmaceutical manufacturing holds the potential to revolutionize the industry. By enhancing operational efficiency and improving quality control, Detect-It AI can lead to more responsive, agile, and competitive manufacturing practices. While challenges remain, the benefits of embracing this technological revolution are significant, paving the way for a more innovative and effective pharmaceutical industry.

Click below to learn more about the Detect-It AI Software development platform.